How to pick the Best Marine Vinyl?

David Goldman

So you’re in the market for marine vinyl and are trying to figure out which vinyl to use for your project.

That’s Wonderful!

You clearly care about your project and want to get the most out of your time and money.

|

99% of people know very little about marine vinyl. Most marine vinyl feels and looks the same so how do you pick out the best marine vinyl for your project? Well it’s your lucky day as you have come to an expert that will give you free and honest advice. |

|

So

If you’re ready to figure out what type of marine vinyl is right for your project, blast through this helpful guide.

#1 Do Not Buy Marine Vinyl based on top 10 lists found online unless its a reputable source. 99% of the time those lists are companies linking to Amazon listings taking a commission. They simply cannot be trusted.

Ok now that I made that clear we can get started by breaking down the vinyl to better understand the material in greater detail. Most Marine Vinyl ranges in thickness from 0.06mm to 1.5mm thick.

You might ask yourself…is thicker better?

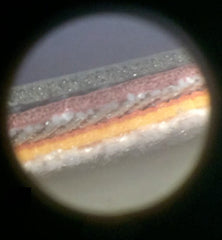

The answer might surprise you. Marine Vinyl consists of a few layers. And it’s these layers that determine the thickness, weight and overall quality of the vinyl. Let’s start by dissecting these layers of vinyl to better understand how each layer impacts the final product.

|

First we will take a look at the bottom layer. It is usually a knitted polyester fabric, but it can also have a fuzzy backing. This layer is very important as it gives the vinyl extra durability and helps to prevent it from tearing. The backing also impacts the stretch of the vinyl. If the backing is woven slightly further apart it allows the vinyl to stretch further and be more flexible. |

|

Next there is a layer of adhesive. This adhesive attaches the backing to the foam layer. This glue has an important job because if this glue fails the backing can peel off from the foam. Some adhesives work better than others. It’s pretty rare for this layer to separate, but occasionally it will happen if the machine that heats and presses all these layers together was not hot enough.

|

The next layer is a PVC expanded foam. This layer makes the marine vinyl thicker. It gives the marine vinyl substance. Have you seen one of those flimsy plastic table clothes with a fuzzy backing? It’s much more pliable and can be crumpled up and tossed around easily. These cheap table clothes and marine vinyl are very similar. The main difference is the table cloth does not have an expanded PVC foam layer. |

Marine Vinyl feels stiffer and stronger as a result of this foam. This layer can be any thickness and changes the “feel” of the material. It gives the vinyl more bounce, flex and stretch depending on what type of expanded foam is used. Thicker more dense foam makes the material feel stiff while more pliable expanded PVC foam gives the material more flexibility and makes it easier to use. I have found the better marine vinyl’s are softer and more pliable, but are extremely durable.

| The next layer is the outer vinyl skin. This skin is the most important as this is the outermost layer that you will sit, hold, wear or use on a daily basis. This skin is usually .05mm thick, but you will find some vinyls with a thinner and thicker skin. This skin can be smooth or textured to allow for different looks. |  |

The skin is made of PVC and it’s how the skin is made that determines whether the material is considered marine grade vinyl. When the outer skin is made additional additives are used to make the material marine grade vinyl. These additives provide UV protection, prevent mold/mildew/bacteria growth, prevent yellowing and help prevent staining. Some brands apply a clear topcoat on the vinyl and trademark them with things like PermaGuard or PermaBlok3. Don’t be fooled, most marine vinyl has the same clear coat and this is a marketing strategy to help make their product stand out. As long as the additives are mixed into the vinyl the material will be considered marine grade and high quality vinyl. If these additives are not added you are looking at regular vinyl that would be used indoors.

Some experts will tell you the weight is the best way to determine the quality of a vinyl. It is a good indicator, but you still need to be careful. It’s very easy for manufacturers to use a thicker and heavier knit backing to add more weight to the vinyl. Some might think that thicker is better, but once again its very easy to adjust the amount of expanded foam in the vinyl to change the thickness.

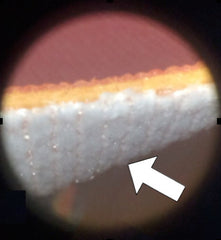

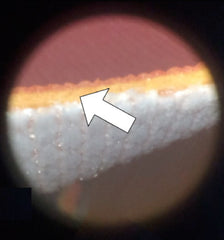

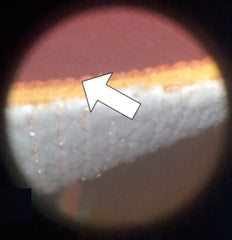

| Now let’s really take a closer look at the marine vinyl under a microscope to see how this plays out in real life. Here are 3 different marine vinyl’s from 3 different companies. The bottom vinyl is the most defined as each layer is a different color. You can also see that the bottom vinyl has a much thicker backing giving it much more weight. The other 2 vinyl’s have the same colored foam as the outer layer, but if you look close enough you can see where the foam becomes one solid piece. If you pick these up and know nothing about them it would be tough to know which one is the best as they all feel very similar. |

Let's look closer! |

So now you’re probably asking yourself…if the weight and thickness are not good indicators to determine good vinyl what should I be considering?

There are two simple ways to identify great marine vinyl!

The first is easy. Look at reviews. If a brand has great reviews and they are talked about positively in blogs and forums it’s likely a great brand. Read the reviews carefully to see if the product works well for your use. Remember this honest feedback is from other people that have actually used the marine vinyl. It’s also recommended to look for products with lots of reviews as that gives you a larger sample size with better feedback. If something has only 10 reviews or none at all think twice before buying. Clearly a five star review is best, but also look for some negative honest feedback. It’s impossible to please 100% of people.

The second way to identify awesome marine vinyl fabric is to look at the product specifications also known as “Specs”. These Specs are scientific based tests that were developed to help people understand how fabric will hold up in different environments.

I will walk you through a few of these tests to help you better understand what to look for when selecting a marine vinyl. The Chemical Fabrics and Film Association have laid out specific tests to help consumers identify marine grade vinyl. Those specifications can be found here.

Everyone’s first question is how will my marine vinyl hold up in the sun?

You need to check the “specs” for the Light Fastness Test (AATCC 16 Xenon Arc or CFFA 2). This test uses a special UV light to replicate the impact of the sun and other harsh environments like salt water and humidity. The material is left in this machine and checked at certain times to better understand how long it takes for the material to fade and break down. Many brands of marine vinyl will state that their material is UV Protected or UV Resistant, but that doesn’t tell you how the marine vinyl will hold up in the sun over time. This test measures the impact of fading over time. When you see a product that claims it has 500 hours of UV protection this is likely the test that was performed to be able to make that claim.

All marine vinyl has an additive to help it last longer in the sun. The more of this additive that is used the longer the material can hold up in harsh elements. This additive is very expensive and drastically impacts the cost of the final product. This UV protection is limited. Any product left in direct sunlight will break down over time. This is why it’s always recommended to cover or store the material inside to maximize the life of the material. If the material is properly cared for you will be able to extend the life of the product.

The next question you might ask yourself might be “Is this marine vinyl durable and will it hold up over time?”

Check the vinyl’s spec sheet for the following abrasion tests (ASM D 4966 Martindale or ASTM D 4157 Wyzenbeek or CFFA 1a #10 Duck). These test methods are crucial to understanding the durability of the marine vinyl. It is most common for marine vinyl companies to use the Wyzenbeek test method, but you will also find some companies that use the Martindale test method. The Martindale test method places a rotating disk with standard wool fabric on top of the marine vinyl and counts how many times the fabric goes around in circles. Each pass equals one rub. The rubs are counted until the fabric fails. This video from my friends at GovMark do a great job describing this test here.

The Wyzenbeek test takes a rod and places a piece of fabric on the end and the rod moves back and forth on the fabric until the fabric fails. The Wyzenbeek test method is counted as a double rub as one pass back and forth counts as one double rub. This is another really helpful video from my friends at GovMark to show how the Wyzenbeek test is performed.

The Wyzenbeek test method is used most often to allow for easier comparison between products, but the better test is actually the Martindale test. The advantage of the Martindale over the Wyzenbeek test is that the Martindale utilizes a special pattern called the Lissajous Pattern. According to Keith Wallace from Advanced Testing Instruments “This pattern allows the sample to be tested in every direction as the same time while the sample is rotating simultaneously. Whether testing warp or weft direction, it is performed with one test. The problem with Wyzenbeek is the sample is rubbed in the same position throughout the test creating elevated friction, heat and built up of coatings or other finishes on the abradant because the abradant does not change position as does the sample on the Martindale with the Lissajous Pattern.”

In my opinion both test simulate people sitting, stepping and scratching at the vinyl making it a better real life use case to how the material is more likely going to be used. The higher the rub counts the longer your material should last. As I mentioned earlier the thicker the outer layer of the vinyl the more rubs one should expect from the vinyl. The only problem is thicker material with a higher rub count is also much stiffer and harder to use as it has less stretch. It is also significantly more costly. A marine grade vinyl needs to be able to withstand 25,000 double rubs.

Another important test that you need to look for on the spec sheet is crocking (AATCC 8-2001 or CFFA 7). Crocking is not something you cook in a Crock Pot. Crocking refers to the rubbing off of color from a wet and dry fabric when subjected to continuous rubbing. Imagine sitting at a fancy restaurant on a beautiful white bench seat. Now imagine 1,000 people sitting on that seat wearing blue jeans and now after 2 weeks that beautiful white bench is now tinted blue. This test measures the impact of bleeding fabric and you want to avoid this as much as possible. You should look to make sure that the marine vinyl has a minimum dry crocking grade of 4 and a minimum wet crocking grade of 3.

Many people love marine vinyl for it’s durability, but since it’s not a normal fabric sewing it is sometimes is a concern. Many people will prefer to use an industrial sewing machine, but some marine vinyl will work with regular sewing machines. However you sew your vinyl is up to you, but you want to make sure the vinyl you choose can hold up when sewn. Some vinyl when sewn can rip easily at the seams and others will hold tight. You should look on the spec sheet for seam strength or seam slippage test ASTM D4034 or ASTM D434 or CFFA 14 as this measure how much weight can be applied at seams before ripping. A good quality marine vinyl should be able to hold 35 pounds of weight before slippage.

When you use marine vinyl in a boat you will hopefully be constantly sitting on those beautiful seats. Well, what if one day as you sat down you forgot about that pointy car key in your pocket. Would your material hold up? This is why you want to check the breaking tensile strength test. The test you would want to look for is the EN388 puncture test or the ball burst test. These tests figures out how much force the material could handle before breaking. A good marine vinyl should be able to withstand 50 pounds of force before breaking. Another similar test measures tear resistance (ASTM D5587). Imagine you had a piece of paper and ripped it in half. This test measures the weight needed to rip the vinyl. A good quality vinyl should take at least 15 pounds of direct force before tearing.

Do you plan on using your marine vinyl in extreme cold? Check to make sure the marine vinyl has a cold crack rating. Most marine vinyl can be left in cold temperatures without any impact, but if the vinyl is moved or beaten aggressively in harsh temperatures it is possible it could crack. So let’s say you are using it for your snow mobile. You might want to make sure it is rated for -10 or -20 degrees Fahrenheit. If the vinyl will be in a boat that is in the cold movement your material should be just fine if it is rated at 0 degrees Fahrenheit. This test is performed with the Gelbo Flex tester using a cold chamber. The sample is crushed and rotated at 440º or 180º. This can be done at sub temps or extreme heat and the goal is to see if the material holds up under these extreme conditions. Once again this only impacts material that will be moved around and abused in extreme cold temperatures.

Lastly you will want to know if the marine vinyl is safe!

There are a few things you should look for when it comes to safety. The first is flammability. Most marine vinyl is naturally flame resistant as plastic typically melts before it ignites, but if the material you bought was from overseas chemicals might have been added that can make it unstable and more likely to ignite quickly. This is why it is important to look for vinyl that has passed the proper testing. If you see on the spec list “UFAC” this is a test for cigarette ignition. This is a simple test to see how long the material will burn if a lit cigarette is left on the material. Another test is “Cal TB117-2013”. This is a test that is required by California law to ensure a material is safe and will not catch fire quickly.

Another test that also measures flammability for automotive use is the “MVSS302” test. This test measures the material burn rate to see how quickly a material will burn. This test is designed for the automotive industry. If you see that the marine vinyl has passed these tests that is great news.

The next safety requirement you should look for is “CPSIA”. This is a test that is required by law that is used to make sure a product is safe for kids. If you plan on making vinyl covered foam blocks, clothing, gloves, bags or many other products for kids under 12 the vinyl needs to pass this test. This test measures lead levels and makes sure it is compliant with ASTM F-963 safety standards imposed by the consumer product safety improvement act of 2008 (CPSIA).

Another similar test that checks for lead and other hazardous substances is RoHS. You should also look to see if a product has passed the test for California Proposition 65 as this test checks the contents of the material for any chemicals known to the state of California to cause cancer, birth defects and other reproductive harm. If you see a product has passed these tests then you are in great shape. Many people often times overlook the safety of a material, but safety is really important and should not be overlooked.

My friend Keith Wallace from Advanced Testing Instruments told me the other day that safety testing is actually the most important point that should be evaluated. “You would never use a parachute that wasn’t tested or hop in a car with an air bag that wasn’t tested or jump on a trampoline that wasn’t tested. Proper testing is crucial to prevent serious injury or death.” I would agree with Keith. If you were smoking on your boat and a small piece of ash fell on your seat you would never want to see it ignite as if lighter fluid were dumped all over.

Now what’s the difference between Marine Vinyl brands? There are dozens of named brands like Nautolex, Sunbrella, Mobern, Enduratex, Naugahyde, Spradling, Ship 2 Shore, Stamoid, Atlantis and Flexa Marine Vinyl. First off, these are all simply brand names that companies have spent millions of dollars marketing. Each one of these brands might offer different colors, patterns and textures. The specs are usually similar, but even within the same brand you will find different products with different specifications. Most of these products are also not sold direct from the factory, which means the prices are marked up more than once.

Remember you want a strong durable safe product that has been properly tested. Now all these materials are very similar if you look at the specs. The biggest difference is price. You can see the price varies from $6.95 to $60+ per yard. The only major difference is how much money each company shoves into their own pockets.

I would love to hear your feedback. Was this helpful? Is there something that I missed? Let me know in the comments.

Sources: Chemicals Fabric Film Association, Govmark, Advanced Testing Instruments

Colleen Thomas

Very helpful as I’m new to sewing with vinyl.

Vicky Wallace

This information was extremely helpful. Thanks.

Linda Parish

I am so thrilled with this fabric. Beautiful quality gorgeous colors extremely fast service. And the price was unbelievably low I would definitely use this place for anything I had to use vinyl for whether it’s marine or not. I couldn’t be happier. Linda Grand lake-st Marys Celina Ohio