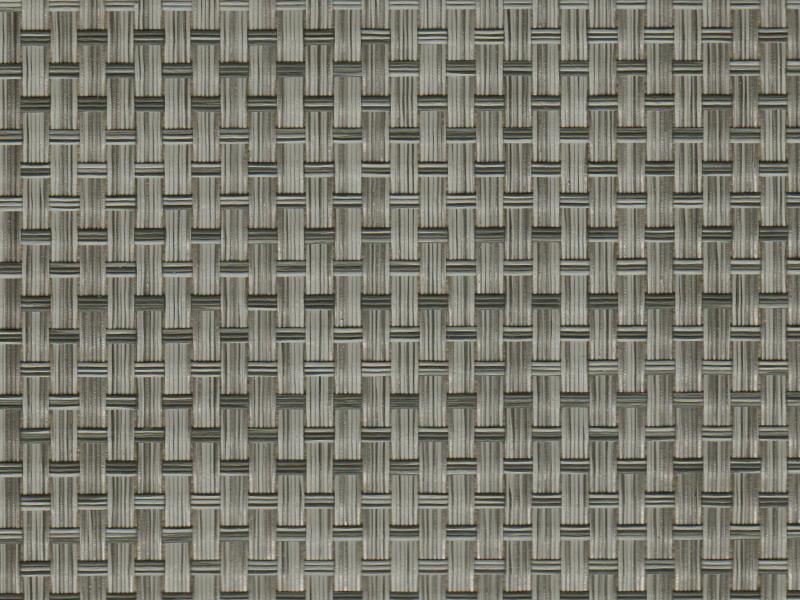

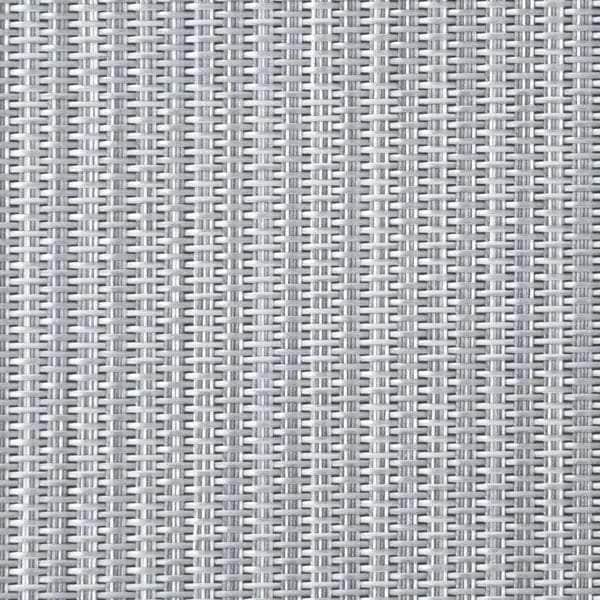

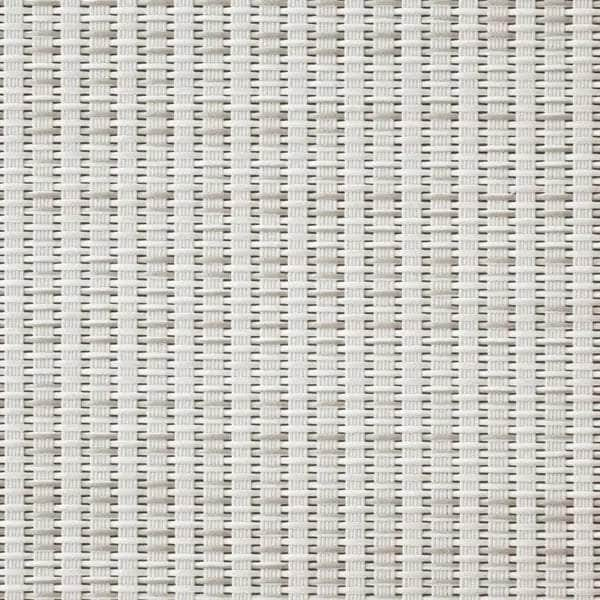

Woven Marine Flooring: (Solid PVC Backing) - Flexa

Feet:

Shipping calculated at checkout.

100+ Additional Marine Flooring Options Available Here

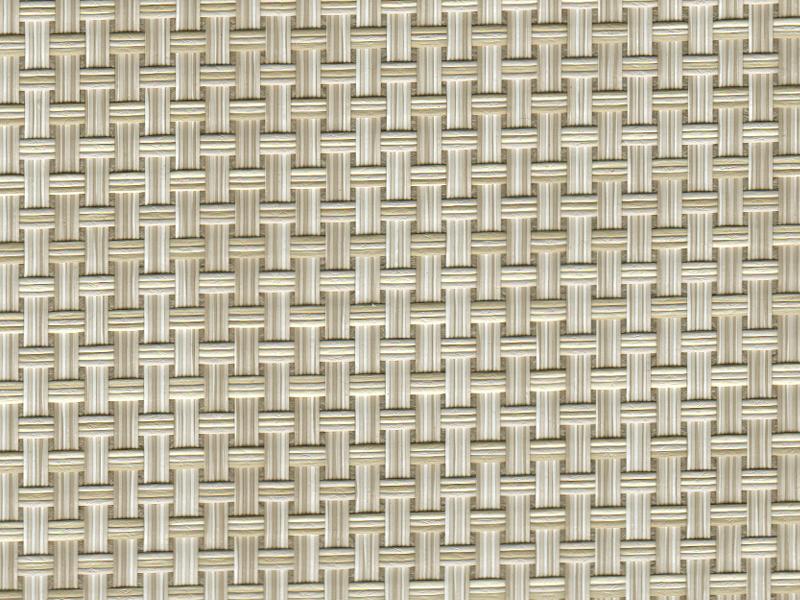

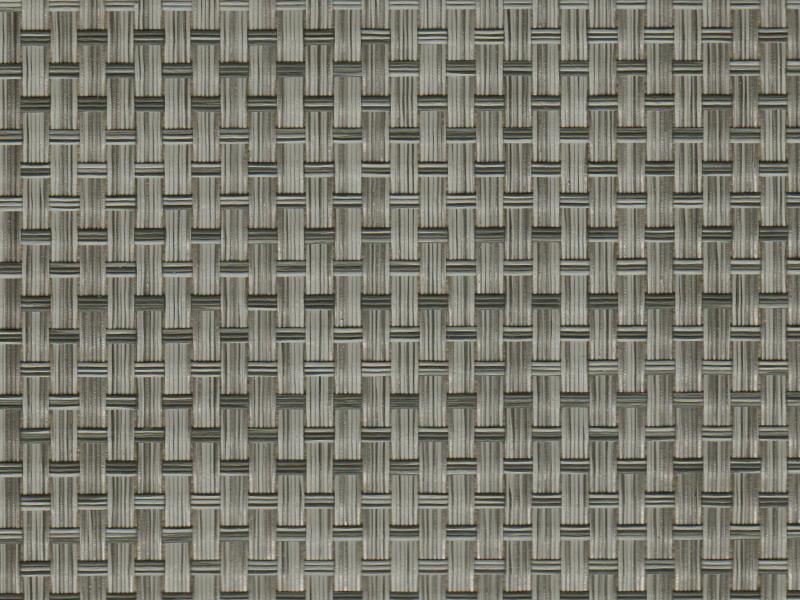

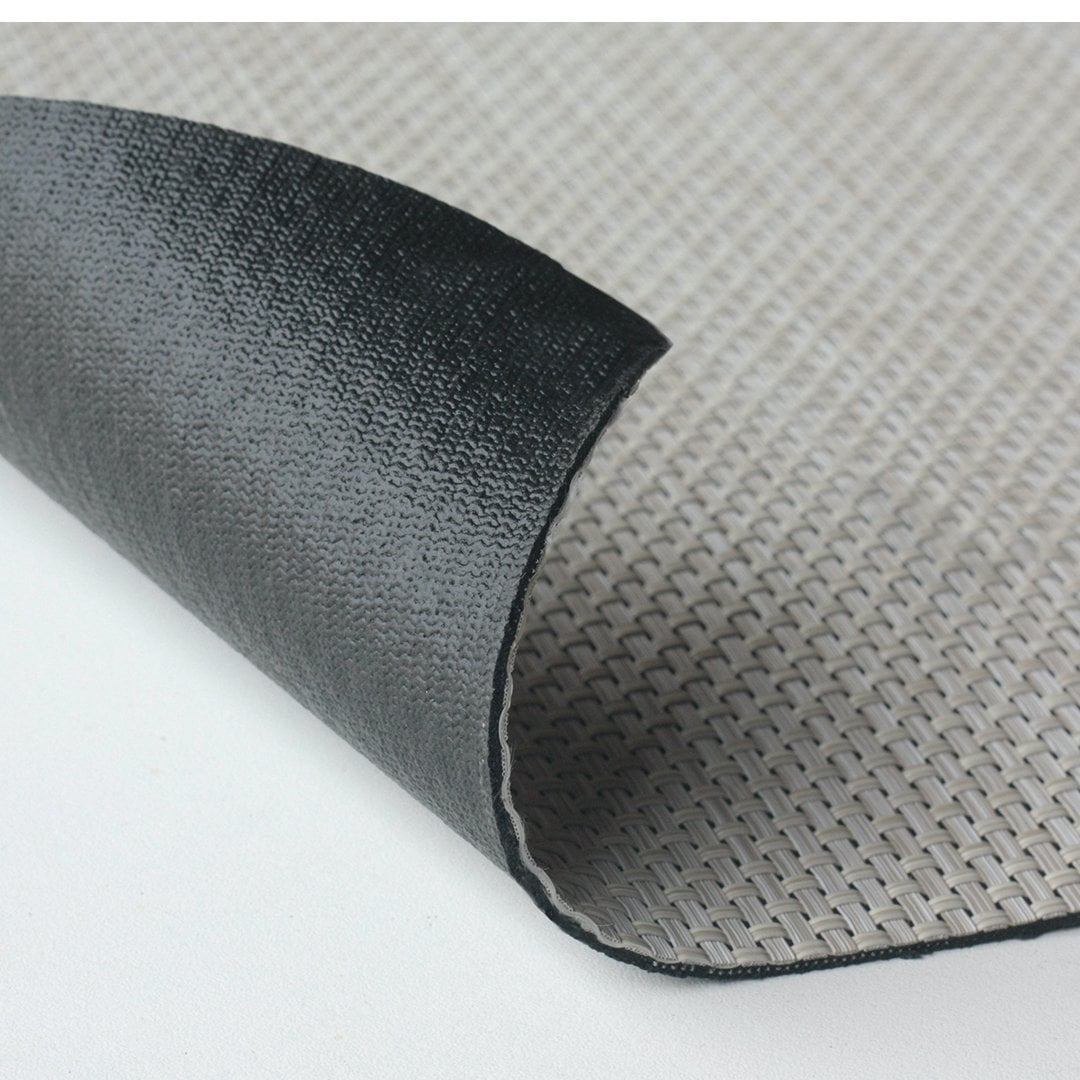

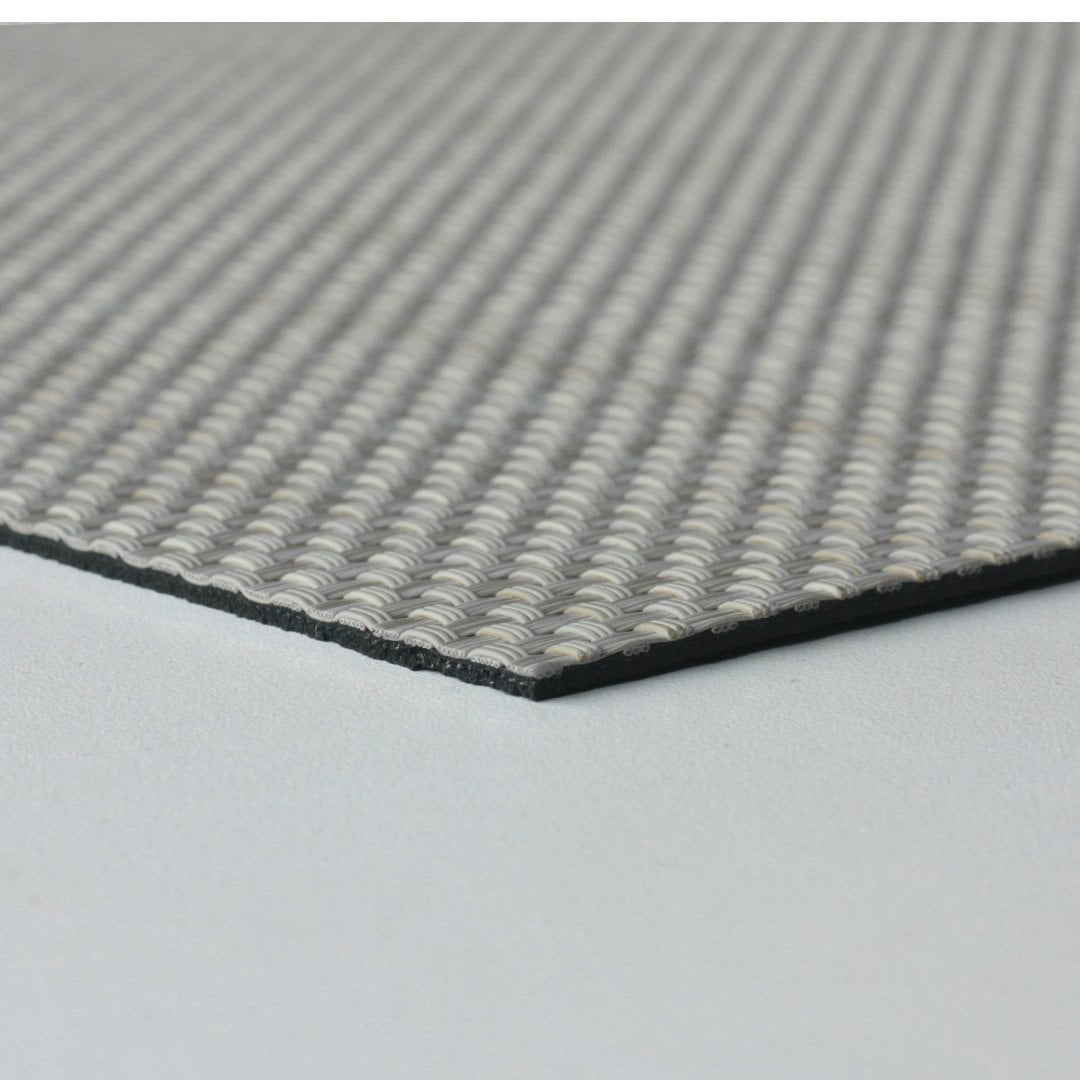

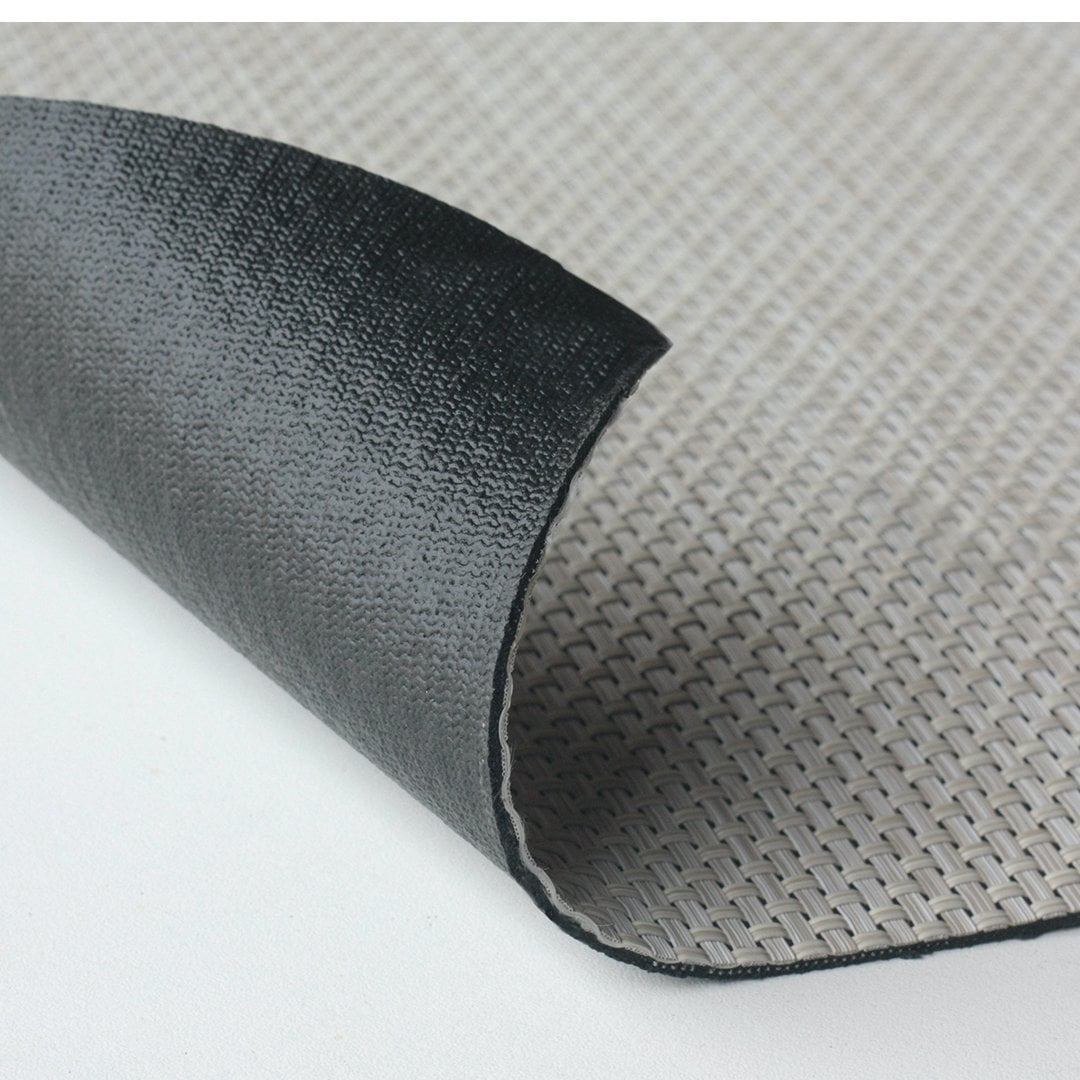

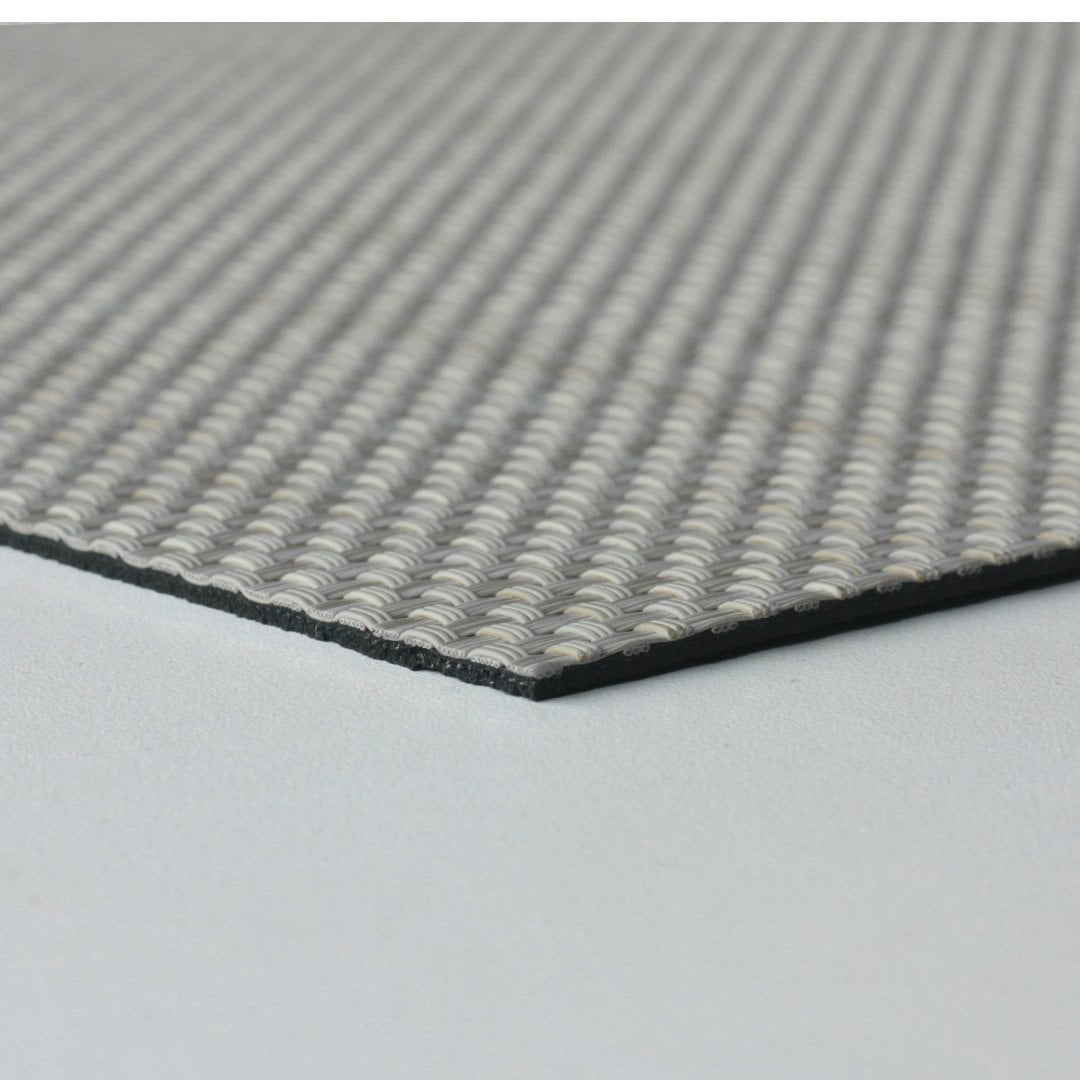

This ultimate luxury marine flooring comes 102" wide. Its slip resistant, UV Stable, Solid PVC Backing and comes with a 10 Year Warranty. Perfect for outdoor and indoor use. Snap it In or Glue it down. Easy to clean and wipe down. The top of the product is a woven PVC and the underside is a closed cell foam which is heat pressed together.

Please note this item takes longer to process and ship due to its size. Most orders are received in about 7-10 business days.

Note: There is a 3 Foot Minimum Order

CHECK OUT OUR FLOORING ADHESIVE

WARNING: Prop 65 Disclaimer

WARNING: Prop 65 Disclaimer

| Specifications | Thick Felt Backing |

Thin Felt Backing |

Watertight Backing |

Mesh Backing |

|---|---|---|---|---|

| Benefits | Luxury Comfort | Economy Comfort | Wipes Dry | Great For Bass Boats |

| Aprox. Thickness | 0.25" | 0.125" | 0.094" | 0.0625" |

| Max Roll Length | 40 Feet | 60 Feet | 40 Feet | 70 Feet |

| Aprox. Weight Per Linear Foot | 3.00 lbs. | 1.75 lbs. | 2.75 lbs. | 1.30 lbs. |

| Minimum Roll Length | 3 Foot Minimum | |||

| Width | 102" Wide | |||

| Warranty | 10 Year Limited Warranty | |||

| UV Stable/Fade Resistant | ✓ | ✓ | ✓ | ✓ |

| Easy To Clean | ✓ | ✓ | ✓ | ✓ |

| Soil & Stain Resistant | ✓ | ✓ | ✓ | ✓ |

| Phthalate Free | ✓ | ✓ | ✓ | ✓ |

| Heavy Traffic Rating | Pass - ASTM 5252 | |||

| No Delamination | Pass - ASTM D3936 | |||

| Excellent Abrasion Resistance | Pass - ASTM D3884 | |||

| Slip Resistance | Pass - ASTM C1028 | |||

| Skid Resistance | Pass - ASTM E303 | |||

| Length | Dimensions |

|---|---|

| 3 feet | 3 feet x 102 inches |

| 4 feet | 4 feet x 102 inches |

| 5 feet | 5 feet x 102 inches |

| 6 feet | 6 feet x 102 inches |

| 7 feet | 7 feet x 102 inches |

| 8 feet | 8 feet x 102 inches |

| 9 feet | 9 feet x 102 inches |

| 10 feet | 10 feet x 102 inches |

| 11 feet | 11 feet x 102 inches |

| 12 feet | 12 feet x 102 inches |

| 13 feet | 13 feet x 102 inches |

| 14 feet | 14 feet x 102 inches |

| 15 feet | 15 feet x 102 inches |

| 16 feet | 16 feet x 102 inches |

| 17 feet | 17 feet x 102 inches |

| 18 feet | 18 feet x 102 inches |

| 19 feet | 19 feet x 102 inches |

| 20 feet | 20 feet x 102 inches |

| 21 feet | 21 feet x 102 inches |

| 22 feet | 22 feet x 102 inches |

| 23 feet | 23 feet x 102 inches |

| 24 feet | 24 feet x 102 inches |

| 25 feet | 25 feet x 102 inches |

| 26 feet | 26 feet x 102 inches |

| 27 feet | 27 feet x 102 inches |

| 28 feet | 28 feet x 102 inches |

| 29 feet | 29 feet x 102 inches |

| 30 feet | 30 feet x 102 inches |

| 31 feet | 31 feet x 102 inches |

| 32 feet | 32 feet x 102 inches |

| 33 feet | 33 feet x 102 inches |

| 34 feet | 34 feet x 102 inches |

| 35 feet | 35 feet x 102 inches |

| 36 feet | 36 feet x 102 inches |

| 37 feet | 37 feet x 102 inches |

| 38 feet | 38 feet x 102 inches |

| 39 feet | 39 feet x 102 inches |

| 40 feet | 40 feet x 102 inches |

Flexa woven marine flooring must be rolled faced out, cushion in. Do not

crease or fold the vinyl. A vinyl to vinyl fold could wrinkle the material.

Marine vinyl fabric flexa luxurious felt backing is designed for comfort. It

typically lays flat, with no edge curling and stays in place, under most

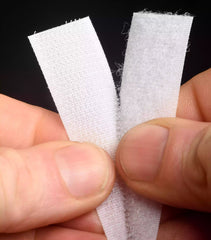

furniture. We recommend a non-slip pad or tape/adhesive be utilized to help

keep in place.

Before you cut this material, STOP and check the following:

1. Quality - is this what you ordered?

2. Color - is this the right color?

3. Pattern - is the pattern correct?

4. Size - is the size correct?

5. Visual Defects?

Note: If material has been cut, fitted, installed, or rolled/folded the wrong way, no adjustments or claims will be considered for any of the above reasons.

I. Preparing for Installation

1. Goods must be rolled face out, cushion in. Do not crease fabric. All claims and warranties voided if rolled any other way or if the product has been cut, fitted, or installed.

2. Before cutting, check the following: Product Quality, Color, Style, and Dimensions.

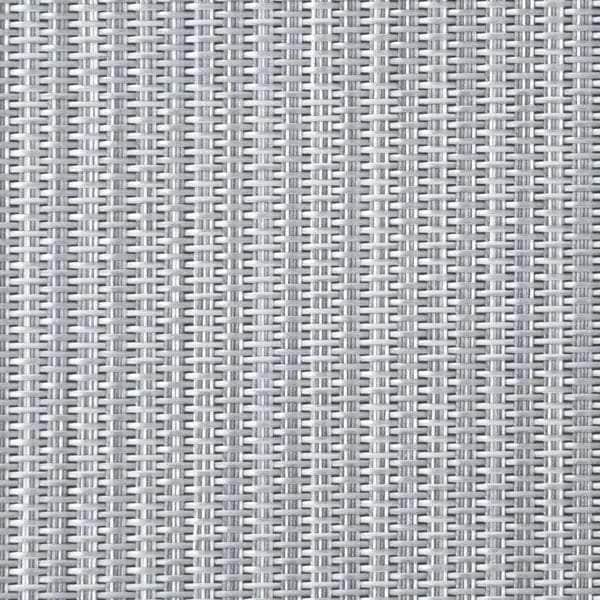

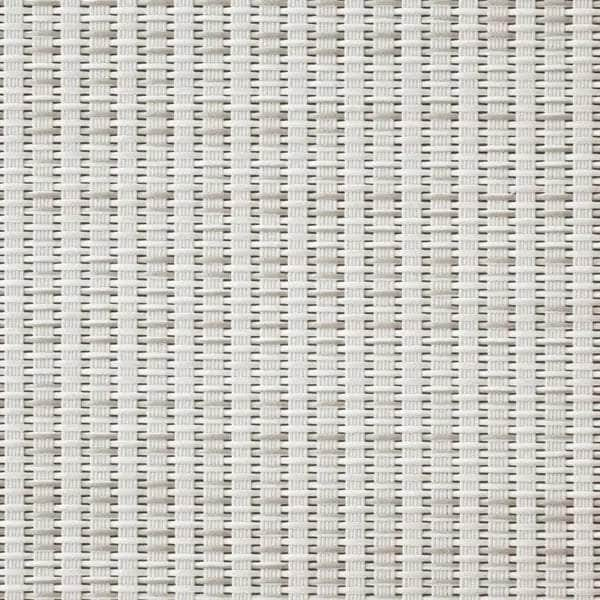

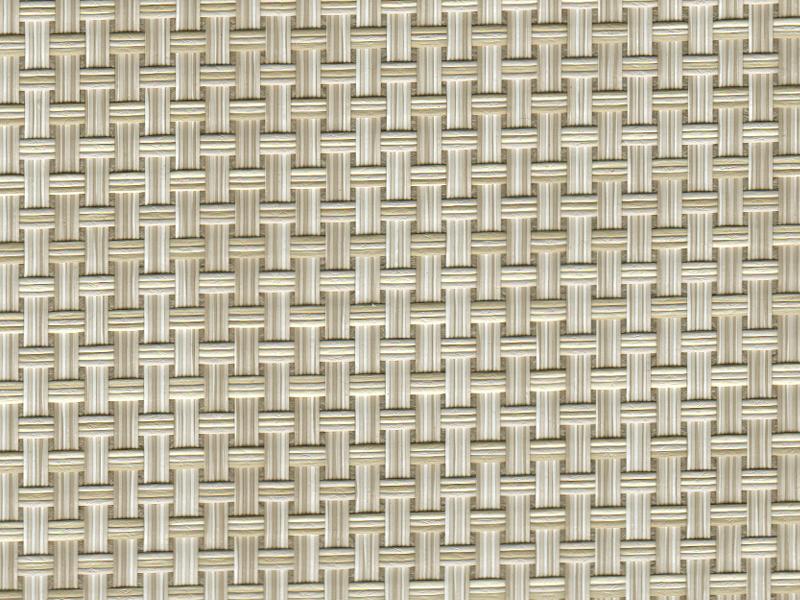

a. Product’s weave may not run parallel to the cut edge. Due to the fabric’s weaving process, some wave, bow, or skew is normal. Tolerance level is 1.5” in either direction.

b. It is normal for some patterns to exhibit light or dark shading. This shading can be more evident at seams where two pieces of the same style meet.

c. Product must be inspected prior to installation. Installation of material implies acceptance. Marine Vinyl Fabric LLC is not responsible for removal or reinstallation cost.

3. Product must acclimate on site for 48 hours at 65°F – 85°F prior to installation.

4. The Marine Vinyl Flooring is 102” wide and has trimmed edges. The edges WILL NOT fray if left exposed.

II. Preparing Floor for Installation

1. For outdoor recreational applications, floor must be smooth, clean, flat and dry - no dirt, dust, wax, glossy paint, or any other foreign material. Uneven surfaces should be sanded smooth or filled until the surface is completely flat, clean, and dry. Non-wood floors must be fully cured, structurally sound, and free of curing or parting agents. Glossy or metallic surfaces should be sanded to dull the surface.

2. If floor is made of multiple wooden planks, ensure that the entire floor is level and that there are no gaps or unfilled space between planks. Joints between planks should be level and smooth. It looks best when installed on a completely flat surface.

3. Approved Substrates: APA Grade Underlayment Plywood, Association Grade Particleboard, Cork Underlayment, OSB, Concrete, Recycled Rubber. For Fiberglass and Aluminum boats we recommend using snaps to secure the flooring.

a. Substrate must be smooth, clean, level, dry and free of dust, dirt, grease, oil, paint, curing compounds, incompatible sealers, fire retardant chemicals, release agents, or any other foreign substance that might interfere with a good bond. Subfloor must be smooth and fully adhered. Depending on the type and condition of the subfloor, mechanical treatment may be necessary, such as, mechanical brushing or grinding with coarse sandpaper. It is the sole responsibility of the installer/contractor to ensure that the concrete surface is properly prepared prior to installation. See ASTM F710-11 Standard Practice for Preparing Concrete.

b. It is necessary that the installer inspects the substrate for cracks or low spots. Apply a cement-based patch compound 24 hours prior to installation. The compound is then sanded and vacuum cleaned.

c. Check floor for hydrostatic pressure and high relative humidity readings in the substrate. Moisture levels of concrete must be below 10 lbs. per 1000SF (According to ASTM-1869 Test Method) and 90% RH (Tested in accordance with ASTMF-2170.) Installation

III. Installing Flexa Woven Marine Flooring on Floors

1. Standard practice is to unroll the woven vinyl and let it relax for 24 hours. This method ensures best adhesive transfer.

a. Product should be laid flat and opened for up to 30 minutes before applying to the floor. This method ensures best adhesive transfer. A 100% transfer of adhesive onto the felt backing must be obtained.

2. This product has a felt back and must be installed using an adhesive that works with felt and for the appropriate indoor or outdoor substrate application. For outdoor applications, adhesive should also be nonflammable and freeze-thaw stable. For additional security, it can also be stapled down to wooden surfaces, applying staples along the edge. Simply be careful using staples because if a staple does not go in all the way it can harm someone not wearing shoes.

3. Adhesive should be applied with a dry paint roller or trowel to the floor only. If a trowel is used, ensuring proper trowel notch will achieve a 100% transfer of wet adhesive to felt. Check with the preferred adhesive manufacturer for the correct trowel size.

a. Recommended adhesives using 1/16 x 1/16 x 1/16 square notch trowel Taylor Resolute AAT 290 (Indoor/Outdoor) AAT390 (Recreational Outdoor) ECO 811 (Indoor) ECO420 (Outdoor). The use of unapproved adhesives void warranty.

b. Allow adhesive to develop tack before placing the woven vinyl. Do not allow the adhesive to dry or develop a skin. Pull woven vinyl back periodically to check for proper adhesive transfer.

4. Installations for all products installed with adhesive must be rolled for proper glue transfer with 35-50 lb. floor roller. Hand roller can be used for smaller installations.

a. All installations require bubbles and air pockets to be smoothed out with non-sharp edge board from center pushing to the edges to ensure felt has made good contact with the floor. Use scissors or razor knife to trim edges.

b. Please note due to the weaving process, some bow and skew may be expected. Keep these variations in mind when seaming.

5. Trim on a flat surface with a straight edge, using a new razor blade for each cut. Always cut product from the face side of the fabric. Dull blades may damage the product or produce rough edges. Clean cuts allow for reduced seam visibility; however, woven vinyl installations typically show seams.

6. For projects requiring a seam in a room setting, mark and snap a straight line on the substrate for the placement of the seam. The number of seams should be reduced to a minimum. Avoid placing seams that are located near entrances.

a. Avoid cross seams and “T” seams if possible

b. Use caution not to crease the material.

c. It is important that the installer spend time working with the seams both in width and length for the best appearance. Lay all the rolls in the same direction before making any cuts

7. Seams need to be aligned with the pattern or texture prior to cutting. A seam can be double cut or straight edge cut. Note: If the pattern is a stripe design do not double cut, cut next to the stripe from the face with a new sharp blade and straight edge. The first drop is laid to the straight-line mark on the floor. Then, the second roll drop, after matching the design, butt to the first drop.

a. Double cut from the face only, with a sharp new blade and a straight edge. Overlap the second strip with the first strip, double cut, and smooth out firmly. If the material has a pattern, make sure the overlap matches the pattern before cutting. The roll drops are overlapped in a parallel way before cutting. Care must be taken to avoid damaging the subfloor. Excess trimmed edge should be removed from the floor and seam closed within one hour. Repeat for each seam.

8. A seam sealer for vinyl is recommended (Mannington MSS-20 or ECO 2285.)

a. All seams must be cleaned, and any dust and adhesive removed.

b. Use masking tape on both sides of the seam to keep sealer off the face of the woven vinyl.

c. Apply a small bead of seam sealer on the seam.

d. Use a seam roller to flatten edges at seams. Seams will be visible using woven vinyl.

e. Allow seam seal to cure without traffic for a minimum of 24 hours.

9. Clean up any wet adhesive with soapy water. A soft bristle brush can also be used. Blot dry with a clean towel and be sure to wash any other surfaces clean of adhesive. Dried adhesive should be removed with an adhesive remover.

10. Traffic for 24 hours after installation should be limited. The glue and seam sealer should be completely dry and hardened before normal foot traffic.

a. Once the installation has been completed, the surface should be protected, particularly if the area is to be used by other trades during final finishing.

Warning

Choose options

Frequently Asked Questions

Water-tight backing offers significant water resistance, but it's not entirely waterproof. Seams and edges may allow some water penetration. For areas with constant water immersion, consider sealed flooring options.Marine vinyl flooring is generally slip-resistant, and water-tight backing shouldn't significantly impact this property. However, some manufacturers may offer textured finishes for additional slip resistance. Consider textured options for high-traffic areas.

- Soft padding = Added Comfort

- High grade Woven Texture

- Non-Slip

- 10 Year Warranty

- UV stable, mold and mildew resistant, Phthalate Free

The backing is made out of a proprietary high density spun polyester cushion that allows for more cushioning and more importantly more airflow to help prevent mold/mildew and rot which can occur when water sits in these types of environments without airflow.

Water-tight backing offers several advantages:

- Enhanced Water Resistance: It repels spills and splashes, making cleanup easier and preventing water damage to subflooring.

- Improved Comfort: Water-tight backing adds a layer of cushioning for a more comfortable walking experience.

- Mold and Mildew Resistance: The tight weave and water-resistant properties help deter mold and mildew growth.

Easy Maintenance: Spills and dirt are easily cleaned with soap and water.

- Felt Backing: Offers comfort but absorbs water and is more susceptible to mold and mildew.

- Mesh Backing: Promotes airflow and dries quickly but offers less water resistance and cushioning.

- Solid PVC Backing: Completely waterproof but can be less comfortable and more prone to heat buildup.

One of the best ways to keep your fabric looking good is to vacuum and/or hose fabrics off on a weekly basis. This helps prevent dirt from becoming deeply embedded in the fabric and eliminates the need for more vigorous cleaning. In most environments, a thorough cleaning will be required as soiling dictates. When it’s time for thorough cleaning, it can be cleaned while installed.

General or Light Cleaning

- Brush off or vacuum loose dirt.

- For outdoor applications, use a water hose to wash away dirt and stains.

- If needed, prepare a solution of water and mild soap such as dishwashing liquid or household cleaner.

- Apply a small amount of water and soap mixture to dirty area.

- Use a soft bristle brush to clean.

- Rinse thoroughly until all soap residue is removed.

- Air dry.

- May not require re-treatment depending on the soiling level of the fabric.

Heavy Cleaning for Stubborn Stains and Mildew

Flexa Woven Flooring does not promote mildew growth; however, mildew may grow on dirt and other foreign substances that are not removed from the fabric. To clean stubborn stains:

- Prepare a solution of 1 cup bleach and ¼ cup mild soap per gallon of clean water.

- Apply a small amount of bleach and soap mixture.

- Blot stain with a sponge or clean towel.

- Rinse thoroughly to remove all soap residue.

- Air dry.

IMPORTANT Remember to protect the area around the area you are cleaning if using a bleach solution. Other fabrics may have an adverse reaction to the bleach.

Professional Cleaners

In evaluating the services of a professional cleaning firm, you should inquire about a firm’s experience in working with Flexa Woven Marine Flooring.

Helpful Hints

Always rinse the flooring thoroughly to completely remove bleach. Please be aware of the environment. Bleach can have harmful effects on the natural environment around you. We do not advise using bleach if you are surrounded by a body of water. Flexa Woven Flooring should only be allowed to air dry.

This information is a guideline, not a guarantee and does not relieve the user from the responsibility of proper care, cleaning and use of the Product and all cleaning agents. Marine Vinyl Fabric LLC , cannot be responsible when unknown changes are made by the manufacturer of the cleaning agent to their formulations. The use of certain cleaning agents, including but not limited to powdered abrasives, solvents, industrial strength cleaners and power washing is not recommended and can be harmful to the surface appearance and the lifespan of the Product. The Supplier and its agents assume no responsibility resulting from the use of such cleaning agents or procedures to the vinyl and use of such will void the warranty.

Potentially. The existing flooring needs to be smooth, level, and free of damage for successful installation of water-tight backed vinyl. Uneven surfaces can compromise the water resistance and create an uneven walking surface.

Customer Testimonials

Learning Resources

Clear Vinyl Fabric DIY Ultimate Guide

Not all clear vinyl fabrics are the same. This comprehensive guide dives into the differences seen in the vinyl and shows you how to pick the perfect clear vinyl for your specific needs. With our...

Read more

You spent a lot of money on your marine vinyl, so you must take the right steps to protect it and prevent damage. Repairing damages and removing stains is difficult to do, so be sure to take the ...

Read more

How to Clean Marine Vinyl Flooring

Maintaining and cleaning your marine vinyl flooring is important to keep it looking fresh and to maintain a high level of quality. In this post, we’re going to go over the best ways to clean your...

Read more